Titanium color coil is manufactured using the physical deposition method where a chunk of titanium is placed into high vacuum to produce coating. This cutting-edge functional product is playing an important role in many areas including automotive, electrical and electronic industries.

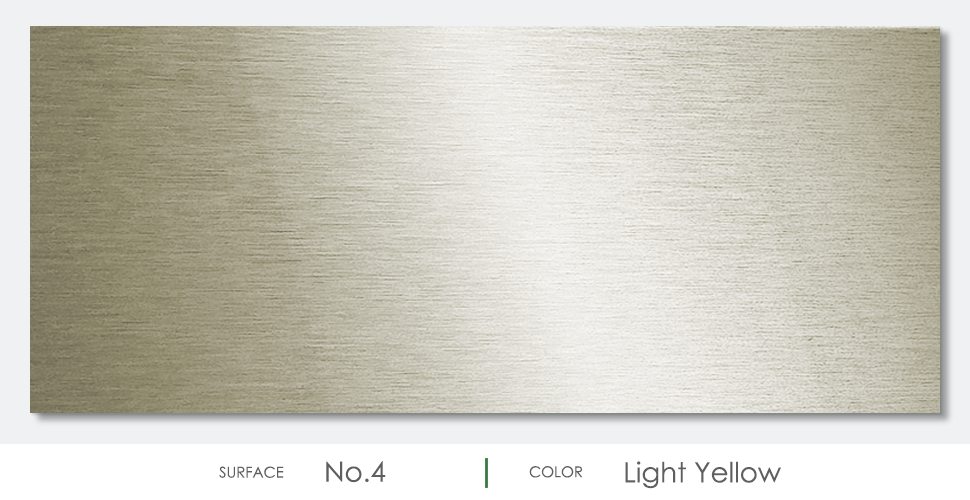

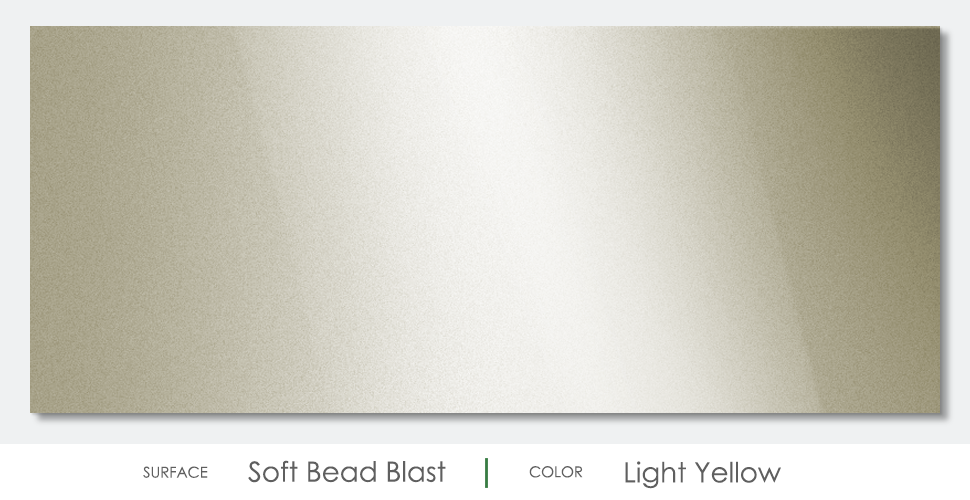

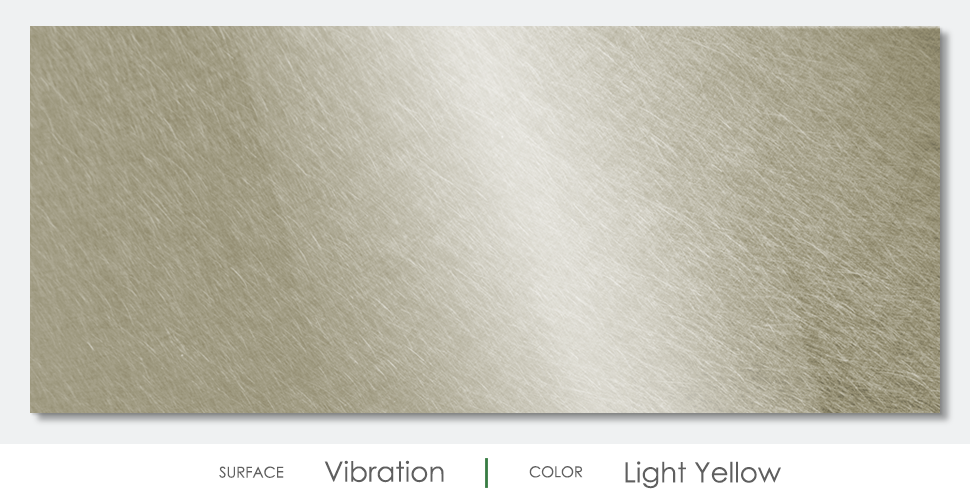

Color

Surface Finish

Product Specifications

| Thickness | 0.8/1.2/1.5/2.0 | ||

|---|---|---|---|

| Size | 1 X 3 (1000 X 3000) |

1 X 4 (1000 X 4000) |

4 X 8 (1219 X 2438) |

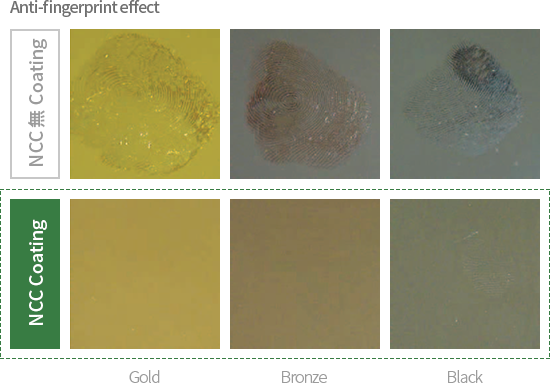

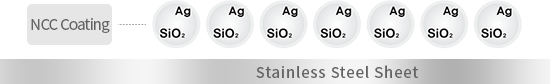

This is an electrochemical coating method using organic/inorganic hybrid technique The surface undergoes anti-bacterial, anti-contamination and anti-fingerprint treatment, facilitating maintenance and washing in comparison to ordinary stainless steel. This strong and elegant stainless steel is then used in construction (interior and exterior), furniture and home appliances to great effect.

N.C.C 1

N.C.C 2

Easy cleaning

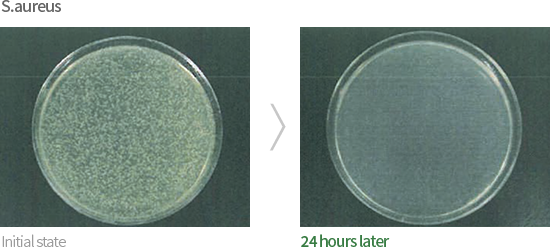

Antibacterial tests

NCC coating antibacterial test

Unit : CFU

| Type of bacteria | Test Sample | No. of bacteria | 24 hours later | Rate of elimination |

|---|---|---|---|---|

| E.coil | STS | 3.9 × 105 | 1.5 × 106 | - |

| NCC STS | < 10 | 99.99% | ||

| S.aureus | STS | 2.0 × 105 | 9.3 × 105 | - |

| NCC STS | < 10 | 99.99% |

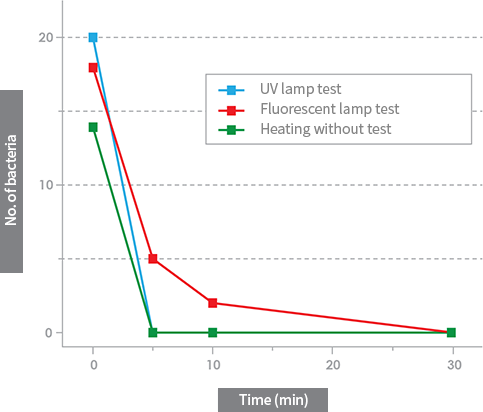

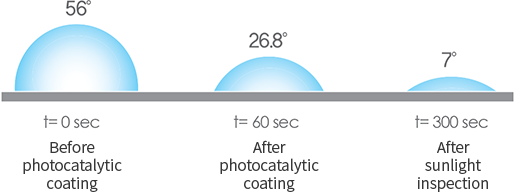

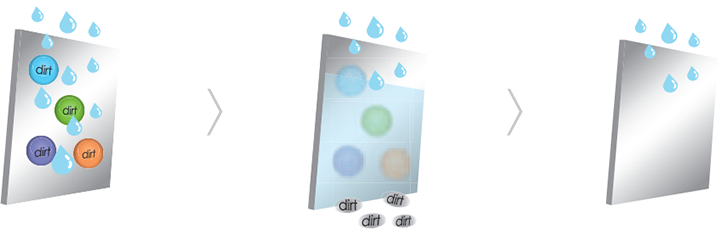

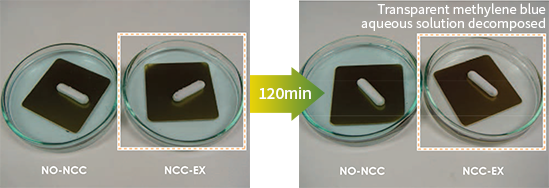

Electrochemical surface coating process using organic/inorganic hybrid techniques. This functional coating has self-cleaning and organic matter decomposition effects ensuring the exterior material remains clean at all times.

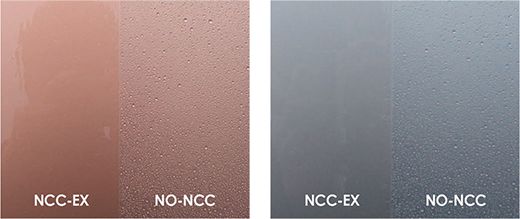

Photocatalyst super-hydrophilic performance test

Fast Functional Coating System NCC-EX

Decomposition under OH radical, activated oxygen (oxidation-reduction reaction)

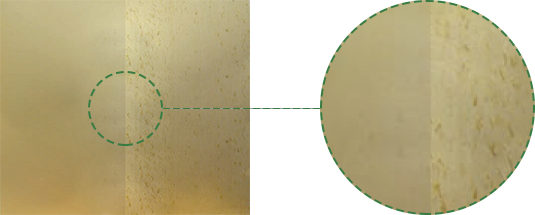

Decomposition of contaminants

Super-hydrophilic effect

NCC Technology

Ti-Color & NCC Coating

NCC Coating

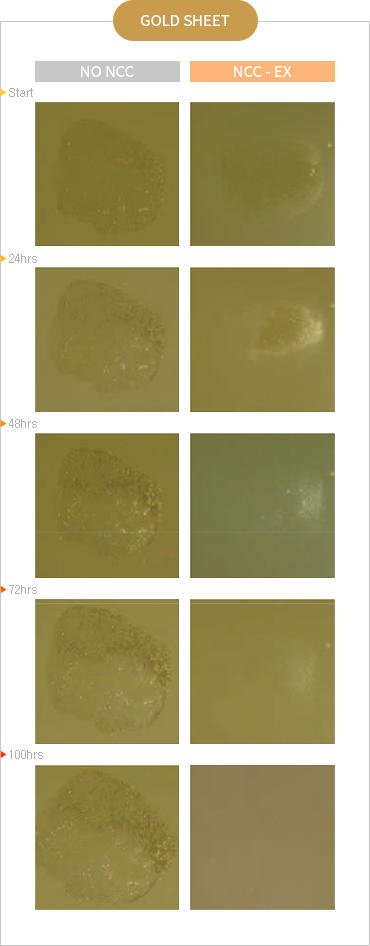

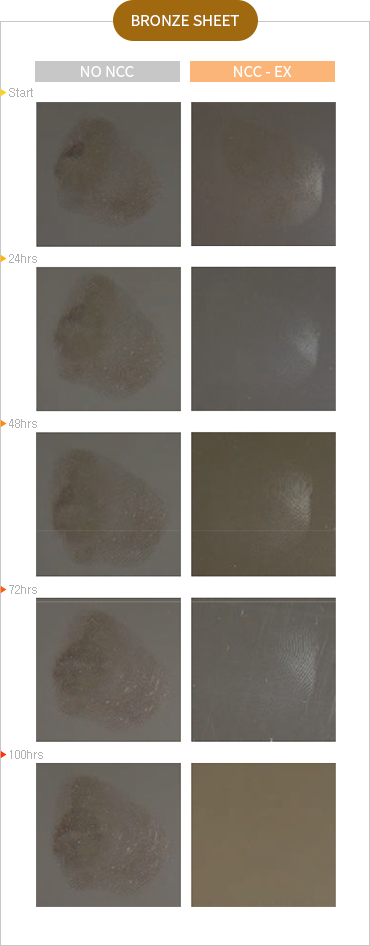

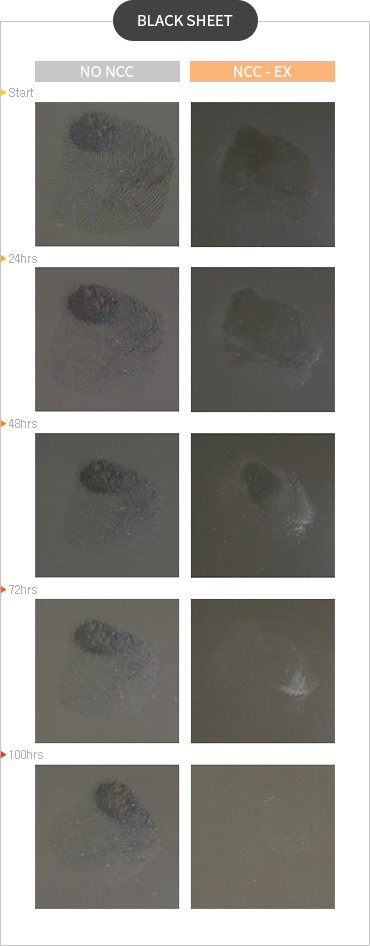

NCC-EX activity evaluation (fingerprint decomposition effect)

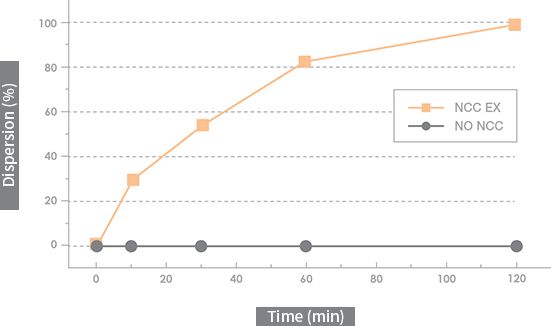

NCC-EX activity evaluation (organic decomposition effect)

Hydrophilic

Self-cleaning

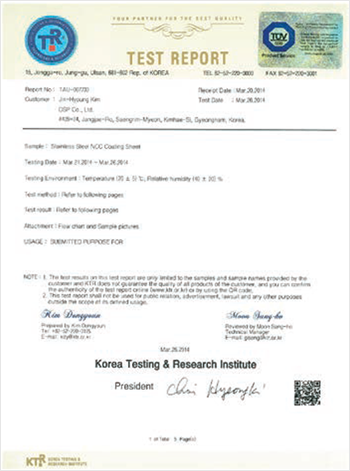

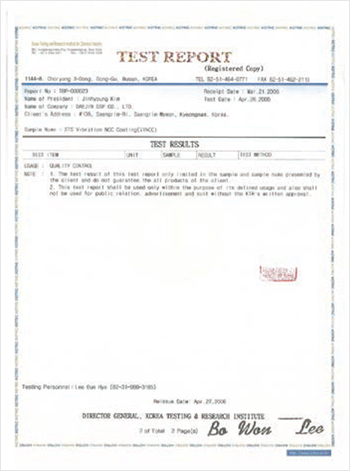

NCC test report