Titanium color coil is manufactured using the physical deposition method where a chunk of titanium is placed into high vacuum to produce coating. This cutting-edge functional product is playing an important role in many areas including automotive, electrical and electronic industries.

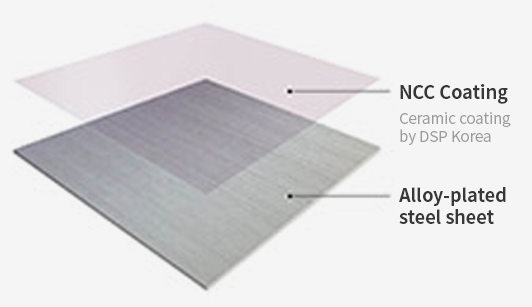

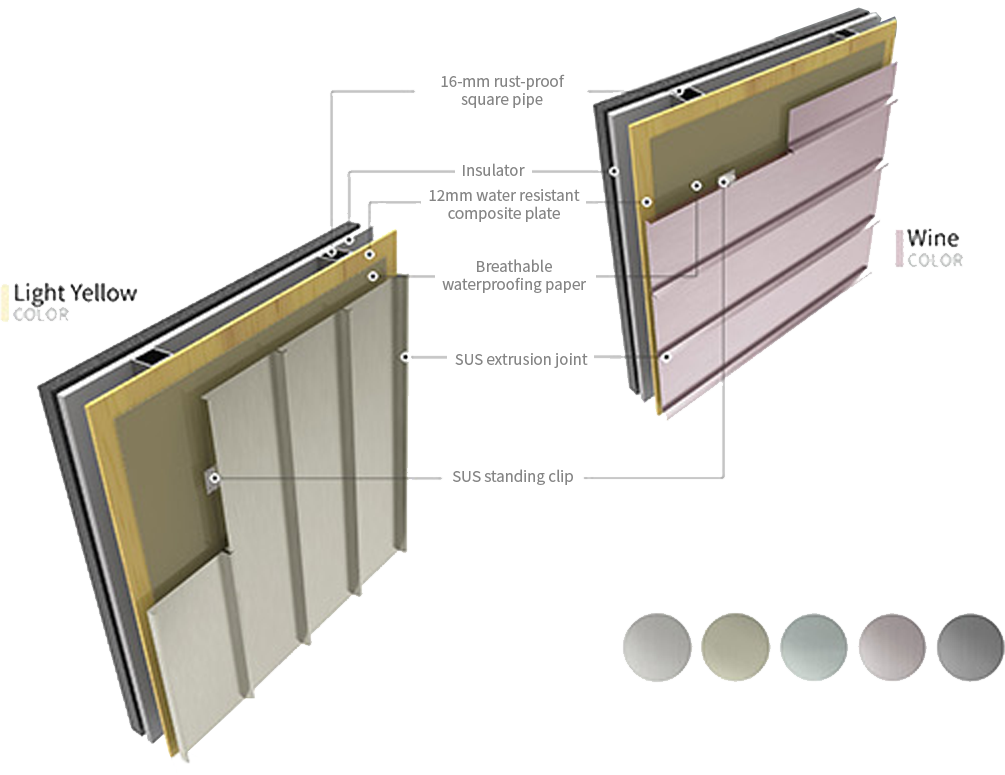

Structure of the product

Characteristics of the product

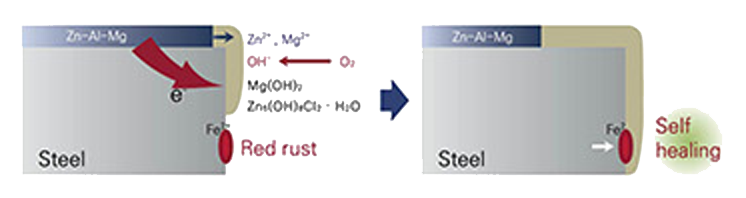

Supermax is by 10 to 20 times stronger than normal GI steel sheets and has a self-healing function that creates its own film on the cross-section.

Supermax has stronger scratch resistance than GI steel sheets.

It provides a beautiful surface in addition to DSP’s special ceramic coating and is free from discoloration.

As it significantly reduces the pollution of molds without Cr, it is eco-friendly.

A product that can perfectly replace GI steel sheets.

Possible to operate effectively due to less maintenance costs due to high corrosion resistance.

Product Specifications

Unit : mm

| Thickness(mm) | Width(mm) | Color | Surface | Raw materials |

|---|---|---|---|---|

| maximum 0.4 / 0.5 / 0.6 │ minimum 0.4 | maximum 620 / 1000 / 1219 | White / LightYellow / Jade / Wine / Grey |

Bead Blast (Dull) | Hop dipped steel sheet |

| Physical properties | Chemical properties | |||

|---|---|---|---|---|

| Steel Base | Coverage | Average | Guaranteed Limit | Percent |

| Longitudinal tensile strength | - | - | - | - |

| Yield strength, MPa | 300 | 170~400 | Carbon(C) | 0.0408 |

| Tensile strength, MPa | 340 | 270~450 | Phosphorus(P) | 0.007 |

| Elongation within 2 inches, minimum % | 30 | 28~ | Magnesium(Mn) | 0.230 |

| Rockwell hardness | - | 50-70 | Sulfur(S) | 0.0066 |

| Supply conditions | Default | Options | Production performance (1-limited / S-excellent / NR-not recommended) |

|

| Tension leveling | Smoothness | Drawing | NR | |

| Pressing | NR | |||

| Surface condition | - | Pittsburgh lock seam | NR | |

| Chemical treatment | - | Roll forming | S | |

| Welding* | S | |||

| Painting** | S | |||

| Surface coating | Nano ceramic coating | |||

| Durability | - | |||

| Ultraviolet resistance | - | |||

| *No metamerism or delamination | ||||

This is an electrochemical coating method using organic/inorganic hybrid technique It is easy to maintain and clean by improving antibacterial, anti-fouling and anti-fingerprint properties of the surface and it makes stainless steel more rust-resistant than normal stainless steel. It helps produce aesthetically elegant colors.

Color

Surface Reflectance / Surface Texture

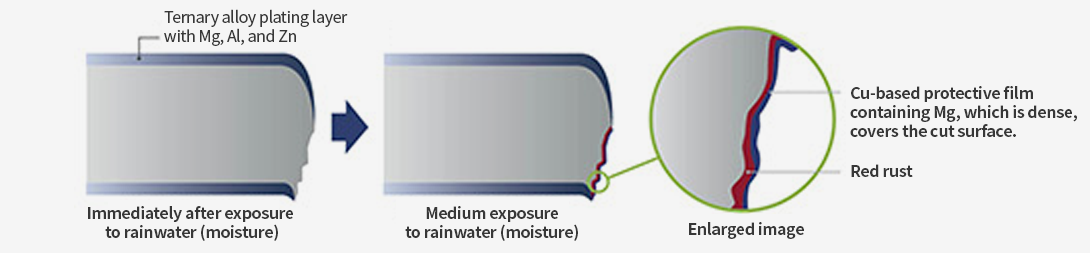

Cross-section cutting mechanism

“Magnesium (Mg) in the plating layer promotes the formation of simonkolleite (Zn5(OH)8CI2 · H2O), a highly stable and dense corrosion product. This corrosion product is formed and maintained like a film on the plating layer to prevent corrosion of steel sheets. In addition, red rust occurs on the area exposed upon cutting. Since then, the corrosion product is covered on the cut surface and this prevents the corrosion of the section.“

Result of SUPER-MAGS reliability test

Unit : mm

| Test Items | Test Methods | Result |

|---|---|---|

| Pencil hardness test | Mitsubishi pencil | 6H |

| Adhesion test | Horizontal cutting (1mm × 1mm, 100) | No problem |

| Shock resistance test | Deformation test | No problem |

| Test of resistance against chemical substances | 5% NaOH spot test (2 hours) | No problem |

| Immersion test in 5% NaCI (360 hours) | No problem | |

| Acetone immersion test (240 hours) | No problem | |

| M.E.K immersion test (240 hours) | No problem | |

| Immersion test in 5% CH3COOH (72 hours) | No problem | |

| Immersion test in 5% Na2CO3 (72 hours) | No problem | |

| Xylene immersion test (72 hours) | No problem | |

| Immersion test in 5% synthetic detergent (240 hours) | No problem | |

| Salt spray test | 5% NaCFOG left unattended for 360 hours | No problem |

| Accelerated weathering test | Weather-O-Mater (artificial accelerated weathering tester) | No problem |

| Accelerated contamination test | Remove black marker pen with alcohol after 24 hours. | No problem |

| Rubbing test | Rubbing M.E.K. 100 times | No problem |

| Rubbing IPA 100 times | No problem | |

| Rubbing acetone 100 times | No problem | |

| Heat resistance test | Cut horizontally after 48 hours at 120 °C. | No problem |

| Cold resistance test | Cut horizontally after 24 hours at -5 ℃. | No problem |

| Heat and cold resistance test | Cut horizontally after one hour at temperature between 120 ℃ and 20 ℃ with 24 repetitions. | No problem |

| Hot water resistance test | Cut horizontally after immersing in boiled water for 12 hours. | No problem |

| Hot and cold water resistance test | Cut horizontally after repeating boiled water and iced water for 30 minutes. | No problem. |

| Fire-proof test | Gas torch for 30 minutes | No toxic gas |

| Weldability | Arc welding | No problem |

| Bendability | 90º bendable without V-cutting | No problem |

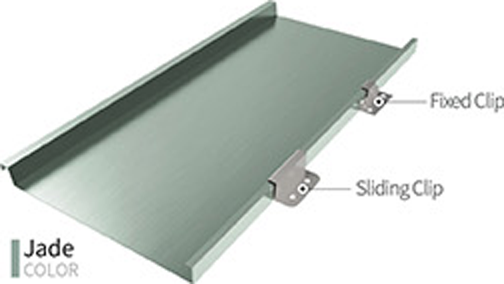

Panel system

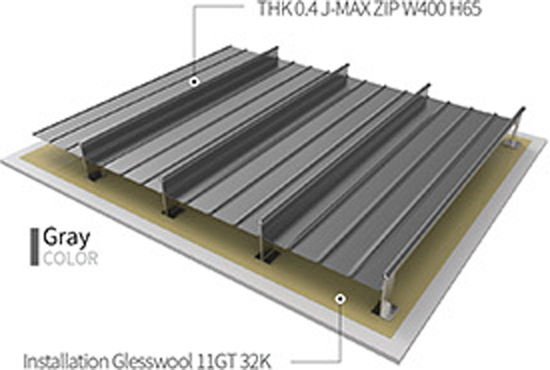

J-MAX ZIP Sound Absorption Insulation System

Extruded joint panel

J-Maxzip System

It is possible to install one sheet seamlessly and without cutting and drilling holes up to 150 meters and it is the most prefect exterior waterproofing system that prevents moisture and contaminants from being inputted from outside. Instead of works of sound absorption and sound insulation separated, both works are conducted as an assembled work. Because the construction period is short, it can be applied to a variety of projects including newly constructed buildings or remodeled ones. A wide range of materials such as SUPERMAGS, aluminum, Stell, colored stainless steel, bonded steel sheet (Stainless + Steel), copper, or titanium zinc, etc. are applicable enough to produce unique buildings. Based on several materials and colors, it has excellent durability and processability and it is possible to produce various designs.

Characteristics of J-Maxzip System Roofing

| Classification | Six characteristics of roofing materials | |

|---|---|---|

| Surface treatment | NCC Coating on 0.4T alloy-plated steel sheet | |

| Finishing method | A method of covering in connection with the roof in a looped joint structure in the horizontal direction on zipper clip. | |

| Features | 1. Perfect waterproof system | There is no risk of leakage at the lower part because there is no screw work on the external fixed part. |

| The expansion and contraction of the material due to the change in the external temperature do not cause rupturing or leakage on the bonded part without fixing screws on the roof. | ||

| 2. Perfect fixing system | Green roof system integrated with the connected whole roof as one structure which includes a clip, a thermal protection pad, and Pulin | |

| The clip head part responds to expansion and contraction of J-maxzip sheet depending on the change in external temperature. | ||

| 3. Perfect durability | It is an eco-friendly material that can be used for 30 to 100 years depending on the material and can be recycled. | |

| J-maxzip Roofing acts as a conductor under normal conditions during rain and lightning. | ||

| It has a long support, and a great resistance to wind pressure and it is possible to handle contraction and expansion flexibly. | ||

| 4. Easy construction | Possible to produce on site by forming. | |

| With the zipping machine which moves forward and backward, it is possible to seal and finish the sides of plates and possible to rapidly finish at a work site. | ||

| Possible to construct without drilling holes in the middle or overlapping with stiff plates because it is possible to make up to 150 meters. | ||

| 5. Convenient maintenance | With the zipping machine which moves forward and backward, it is easy to disassemble by part to save maintenance costs and it is possible to be rapidly handled. | |

| 6. Free curved surface rendering | Possible to produce in a curved shape with our unique advanced equipment. | |